Production

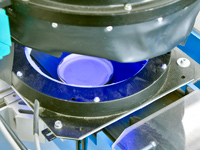

The factory produces 82, 66, 63,43 mm and SKO-82, the average output is 300 caps per minute or about 100-110 thousand caps per shift.

The process of production is fully automated, including quality control, scrapping and waste removal from the conveyor, and counting the caps before packing. Then, the caps are packed in cardboard boxes, which can contain from 750 up to 3500 caps, depending on the diameter.

High-tech equipment of German «Rainer Naroska» company and modern materials are used for the production of our caps. German Rasselstein company's EN10202 TH 508 2,8Х2.8 tin is used: 0.18 mm for №82 caps, and 0.155 mm for №66 caps.

|

|

|

|

German high-tech equipment with output of up to 300 caps per minute is used for the production of the caps. To produce the caps, modern materials imported exclusively from "Rasselshtain", "Corus" and other German companies are used.

Compounds and lubricants for tin, dyes, coating and adhesion varnishes for lithographing are supplied by German HOBA Lacke und Farben GmGH, DS-Chemie, and AFT companies. Varnishing and lithographing is made on German Maylender company's equipment allowing to have gamma of six colors, which allows you to put your corporate identity in full-color.

|

|

|

|

The quality of the production is appraised with awards and diplomas from specialized exhibitions and conferences, and is implemented by long-term contracts with our partners.

|

|

|

|